MEETING REAL NEEDS AND ACHIEVING ROI:

IMPLEMENTING A MOBILE PERFORMANCE SUPPORT SOLUTION

CUSTOMER PROFILE

MTAB, a company headquartered in Chennai (India), is a leading manufacturer of Computerized Numerical Control (CNC) machines, an advanced machining process in which computers are used to make precision cuts and dies on tools.

THE PROBLEM

TMTAB had three issues with their post-sale process:

- Length of the billing cycle (about 12 weeks after the machine was delivered to the customer)

Every sale made by MTAB was considered complete only when the machine was commissioned and ready for use by the customer.Customer personnel, though qualified, were not fully able to commission the machine. Once they received the shipment, they naturally started the commissioning process, but at some point, had difficulties and were unable to proceed. The MTAB Service Center therefore ended up receiving several calls for support, who then sent an engineer traveling to the customer’s location to help them. The entire commissioning processtook 12 weeks on an average, due to various logistical challenges (many of MTAB’s customers were located in remote corners of the world).This meant that MTAB could raise the final invoice only after 12 weeks of delivering the machine.

- Number of calls to the Service Centre (which were very high)

On analyzing the requests, it was found that over 50% of such calls (approximately 600 calls a year) were pertaining to the customer’s lack of understanding of how to run the machine. Though users were familiar with CNC programming, they were not well-versed with the details of operating the equipment.

- Efficiency of the Service Centre (which was low, due to the points above)

Engineers were spending excessive time over calls and traveling to customer sites, to resolve basic queries (queries that would not have arisen if the customer had been more familiar with the operation of the machine). In fact, they were spending an average of 1800 person days on these avoidable tasks.

MTAB had in mind an e-learning solution to address these issues, and consulted Learnnovators for the purpose.

THE INVESTIGATION

Learnnovators,taking on the role of performance consultants, went about analyzing the situation, determining the root cause(s), and establishing the real need before concluding that a course is indeed the solution.

The first step in this process involved a deep dive into the case, consolidating the pain points and unearthing theirroot causes. The findings included the following:

- One of the most important factorsfor a sale to be considered complete was the commissioning process. Once this process was done, the sale was deemed complete, and MTAB could raise the final invoice.

- This commissioning process was the one that was causing the lag. That is, customers were making a huge number of calls to the MTAB Service Centre with queries on this process.

Once this understanding was in place, a more detailed analysis began, interviewing:

- Personnel at the customer’s end who were assigned the task of commissioning the machines

- Service engineers at MTAB who were responsible for providing support to these personnel

Afterthis analysis it was found that though users were qualified engineers trained in CNC commissioning and operation, there were gaps in their knowledge that led them to call the MTAB Service Centre frequently.

And, the same issue (gaps in knowledge) was contributing to all three of MTAB’s challenges:

- Extension of billing cycle

- Frequent calls to the Service Centre

- Overstaffing of the Service Centre

The emergent goal was to equip customers to commission the devices themselves. However:

- Training was not the solution; the primary target group (customer personnel) were already trained in the respective areas.

- Users required a solution that would address their queries while at their job, to help them complete the commissioning process on their own, with minimal help from MTAB.

THE SOLUTION

Users needed a solution that gave them the right information at the right time. The answer clearly was a performance support solution.

Considering that it was a hands-on, visual and dynamic process, it was determined that video was the best way to explain it. A paper-based solution was ruled out right at the beginning for this reason.

Having said that, the location at which the commissioning took place typically had no computer. Even then, running to a computer to find answers multiple times would be cumbersome. So, mobile devices emerged as the medium on which users would access the content.

The solution was a mobile app-based, just-in-time system titled MPSS (Mobile Performance Support System). Using an app installed on their mobile devices, users could scan relevant QR codes and access the appropriate content in their moment of need.

Figure 1. Image showing the home page of the MPSS app

The commissioning process comprisedof 16 steps. Combined with pre-installation requirements, Learnnovators identified 20 micro areas (or steps) in which users needed support, and developed byte-sized videos (1-2 minutes’ duration) for each area.The content of the support calls received by the MTAB Service Centre was also analyzed, and used as input for making the videos.

In addition, a PDF document corresponding to each step explaining the content of the video in text format was created, to serve as a supplementary resource for quick reference.

Each video,along with the corresponding PDF,was made accessible on mobile devices via QR codes.

TheseQR codes were:

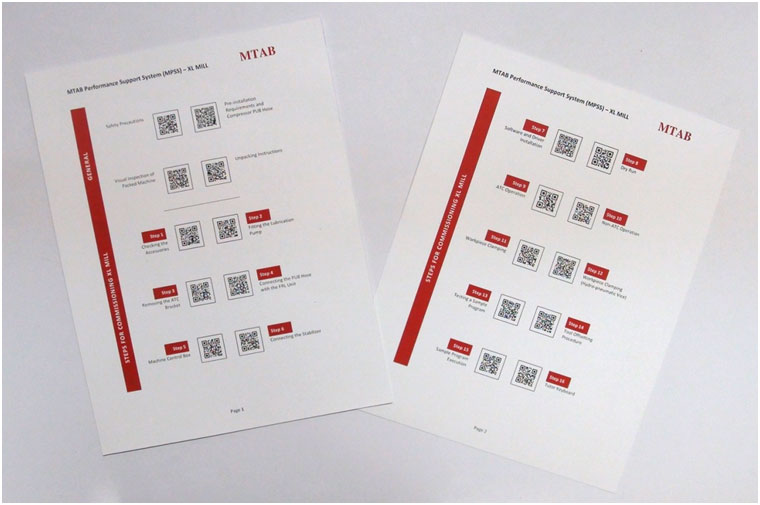

- Placed as stickers on appropriate parts of the machine, and

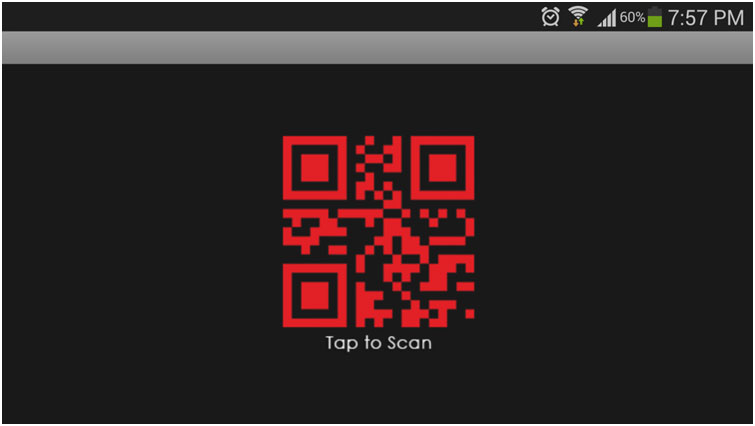

- Printed on a reference sheet shipped along with the machine

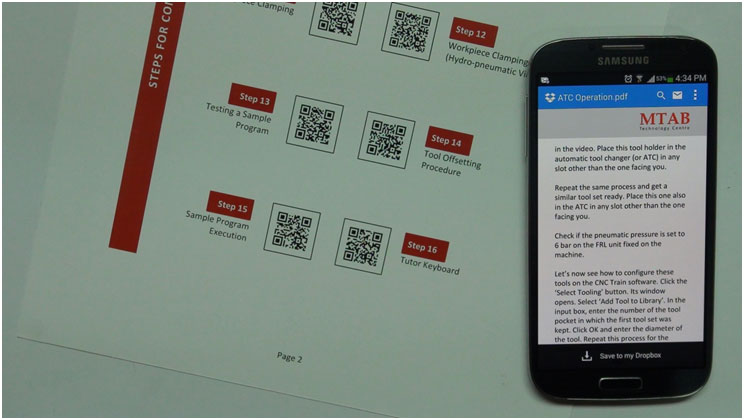

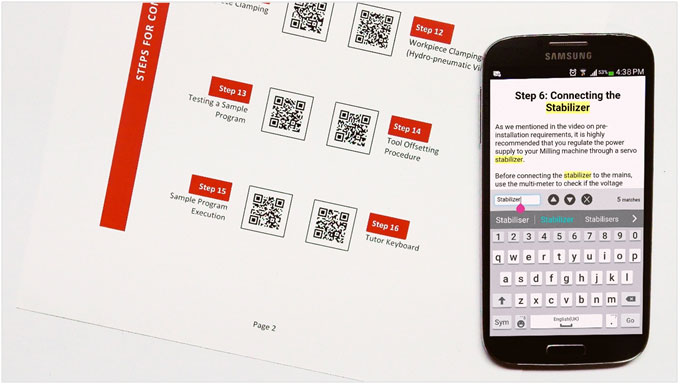

Figure 2. Image showing the reference sheet that is sent to customers along with the product

Figure 3. Image showing a QR code placed on the CNC machine

Figure 4. Image showing two QR codes placed on the CNC machine

Figure 5. Image showing the app after a QR code is scanned from the reference sheet

Figure 6. Image showing the open PDF for the QR code scanned from the reference sheet

Figure 7. Image showing the video playing for the QR code scanned from the reference sheet

If the user needed support at any step of the commissioning process, they could, using the app installed on their device,scan the QR code placed on the corresponding part of the machine, and access the appropriate video or PDF explaining that step. And if they needed to go through all the steps in sequence, they could do so by scanning each QR code on the reference sheet.

In addition, though the queries received by the MTAB Service Centre had been analyzed and incorporated into the videos and PDFs, Learnnovators knew there could be more queries, and brainstormed ways to make the solution more dynamic and scalable, in order tomake it possible for MTAB to update it at their end.

Learnnovators also wanted to make it easy for users to access portions of the content by making it searchable.

So, in addition to the PDF and video options, a third option titled FAQ was included. Users would see this option when they scanned a QR code, and tapping it would take them to the FAQs for that particular step. Here, they would also be able to search for and find answers related to other steps in the commissioning process.

Figure 8. Image showing the app with the third option – FAQ

Figure 9. Image showing the screenshot of the FAQ for the QR code scanned from the reference sheet

To sum up, the solution offered:

- Byte-sized instructional videos that explained the process in a step-by-step, lucid manner

- PDF versions for users who want to just skim through the content

- Searchable FAQ comprising all the latest queries and their responses

THE DELIVERY

The majority of the users were located in remote places, with limited Internet connectivity, so the content had to be made available at the moment of need without dependency on the Internet. Therefore, Learnnovators decided to embed all the content —the videos and the PDFs — within the app itself, and not stream them from a server.

In addition, though the solution was designed and tested to work across a variety of devices, to make the experience seamless for users and save them the hassle of downloading content from the Internet, Learnnovators encouraged MTAB, who readily agreed, to ship a complimentary mobile device pre-loaded with the app and all videos and PDFs,along with the machine.

So, each shipment of a CNC machine included:

- A complimentary mobile phone pre-loaded with:

- The MPSS app for the appropriate product

- The videos and PDFs

- Apps for scanning QR codes, playing videos and viewing PDF files

- A reference sheet comprising the list of all QR codes, arranged in sequence

- QR code stickers pasted on appropriate locations on the machines

- Safety paraphernalia (such as gloves, goggles etc.) to promote best practices for installation

THE BENEFITS

MTAB was able to achieve the following in the nine months since the solution was implemented:

- An 8-week reduction in the billing cycle, resulting in direct improvement of the sales process, and augmenting collections

- A 52% drop in the number of support calls to the MTAB Service Centre

- A 56% improvement in the productivity of MTAB’s service engineers, owing to:

- The fact that they can now be trained using this system, within four weeks of joining, instead of the traditional face-to-face training lasting three months

- A reduction in travel time for servicing basic requests by customers

The results achieved by the program are summarized in the table below:

| # | BUSINESS METRIC | FROM | TO | OUTCOME |

| 1 | Billing Cycle | 12 Weeks | 4 Weeks | 67% Reduction |

| 2 | Support Calls to MTAB | 600 Calls | 290 Calls | 52% Drop |

| 3 | Service Centre Efficiency | 1800 Person Days | 785 Person Days | 56% Improvement |

Ultimately, because of the solution, MTAB realized savings of INR 17.5 Million (USD 291,000) in travel and associated costs of service engineers, as well as in productivity gains in the first nine months of its implementation.

THE HIGHLIGHTS

The MPSS program was a stupendous success. Here were the highlights of the program:

- Adoption: The use of QR codes to access a specific video that answered a question in the moment of need was new, and novel for the audience. This helped bring people on board, just to try out something they hadn’t seen before.

- Execution: Though the novelty factor can bring people on board, the program will fall flat unless it is executed well; this was ensured by embedding all the content (including videos and PDFs) within the app and not relying on the Internet. All this was also pre-loaded on a complimentary mobile device, further piquing the curiosity of users.

- Effectiveness and Sustained Success: Finally, any program can become a long-term success only if it delivers on its promise – of providing scaffolding in the moment of need in this case. The program did this very well by the use of easy-to-understand videos that users can access when they need help.

Finally, one important lesson learned is that even highly complex problems can be solved by extremely simple solutions. In the case of MPSS, the solution was a cost-effective one that took minimal resources to implement. However, it was the power of an idea, combined with detailed planning and execution, that delivered the results.

ADDITIONAL INFORMATION

Here’s a 2.5-minute explainer video demonstrating the solution: https://youtu.be/IpZD7wx49pc

Here’s a 2-minute video containing a testimonial from MTAB’s CEO, Ms. SashiSairaman: https://youtu.be/tJ2KZQUGGM4.

TOOLS / TECHNOLOGIES USED

MIT AppInventor, Adobe Premier, Adobe Photoshop, Microsoft Word, HTML

AWARDS WON

- Won Platinum in the LearnX Impact Awards 2016 for “Performance Support”

- Was Finalist in the LearnX Impact Awards 2016 for “eLearning on a Budget”

- Won Gold in the 2015 Brandon Hall Excellence Awards for the “Best Use of Performance Support” category

- Won the DevLearn 2015 Hyperdrive contest for its “Mobile Performance Support System” (MPSS) solution